Mass Timer Connection Detail

This project focused on designing a custom three-direction beam-to-column connection using a heavy seated knife plate inspired by my research into the T3 Minneapolis mass timber project. I studied the limitations of concealed hardware in early precedents and proposed a simplified, visible steel connection that balances structural efficiency with ease of installation. The design uses a Simpson-style knife plate to transfer vertical loads, eliminating the need for beam routing and reducing labor costs. This exploration deepened my understanding of structural detailing in mass timber architecture and highlighted the evolving relationship between performance and aesthetics in connection design.

CaSE Study - t3 minneapolis

T3 Minneapolis is a landmark in modern mass timber construction and was the largest contemporary timber building in the United States at the time of its completion. This 220,000 square foot, seven-story office and retail building was constructed using a spruce-pine-fir glulam and nail-laminated timber system, emphasizing speed, sustainability, and aesthetic innovation. Built in just 9.5 weeks, T3 demonstrated the viability of timber as a scalable structural material in urban commercial development. Our case study explored the building’s material systems, construction process, and the evolution of the T3 brand across other national sites.

Full case study presentation:

My Design

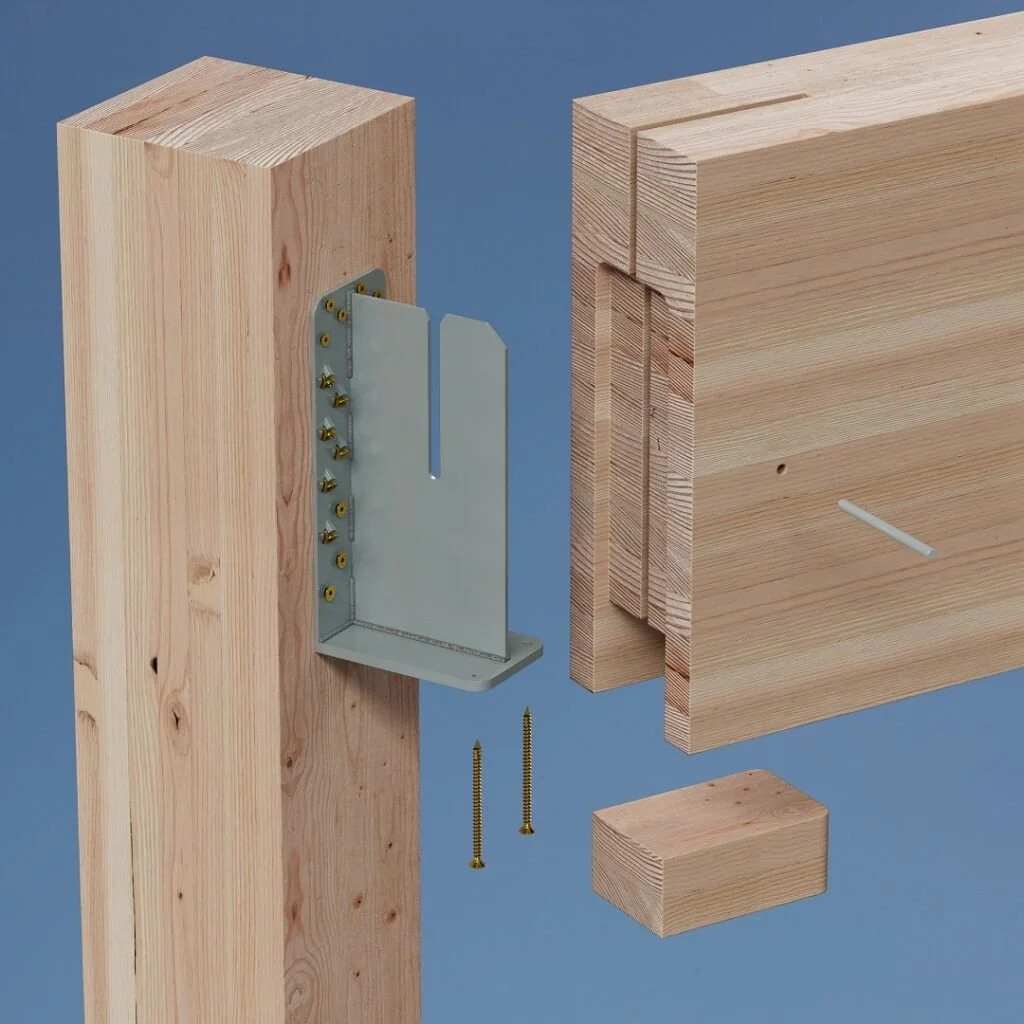

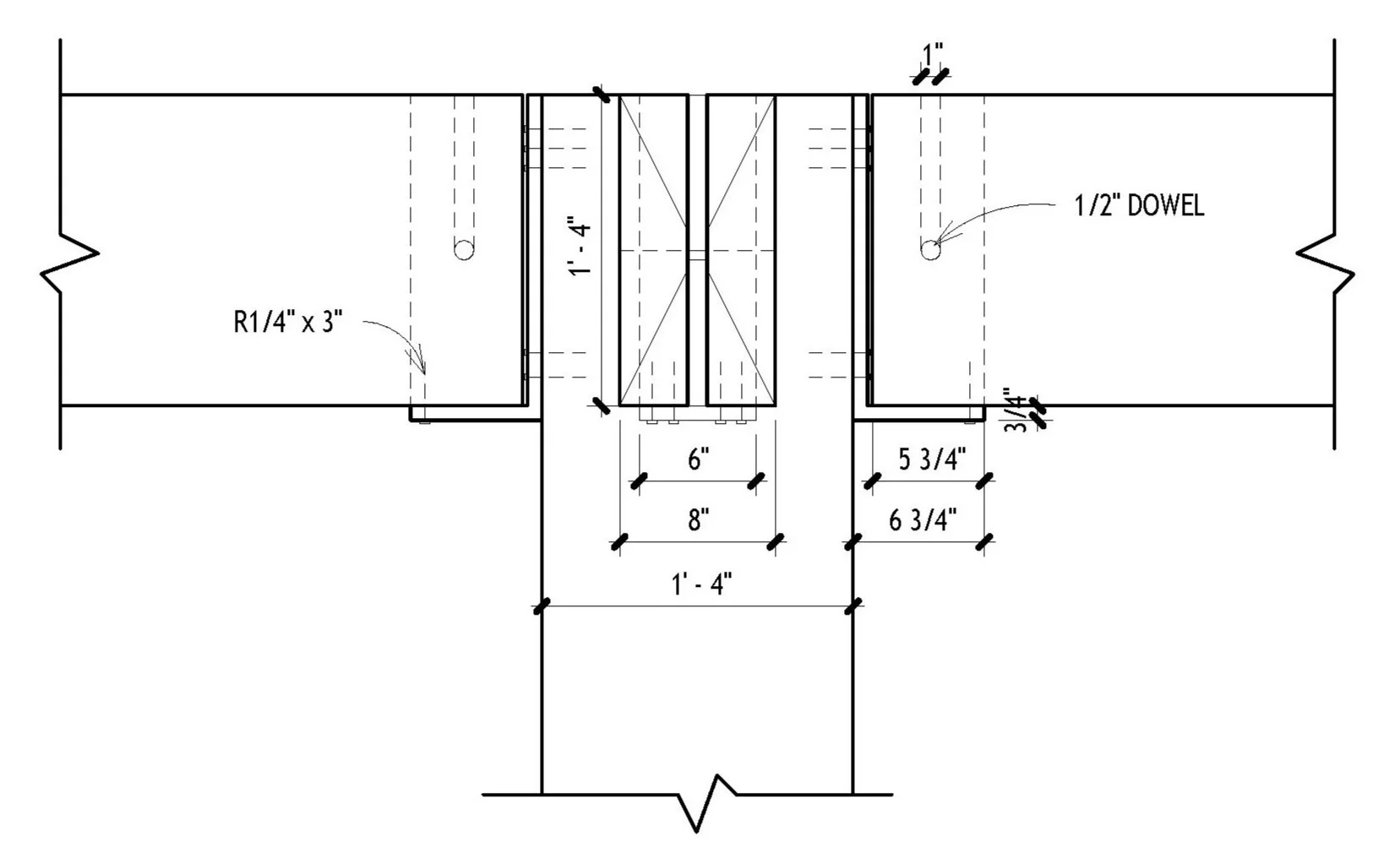

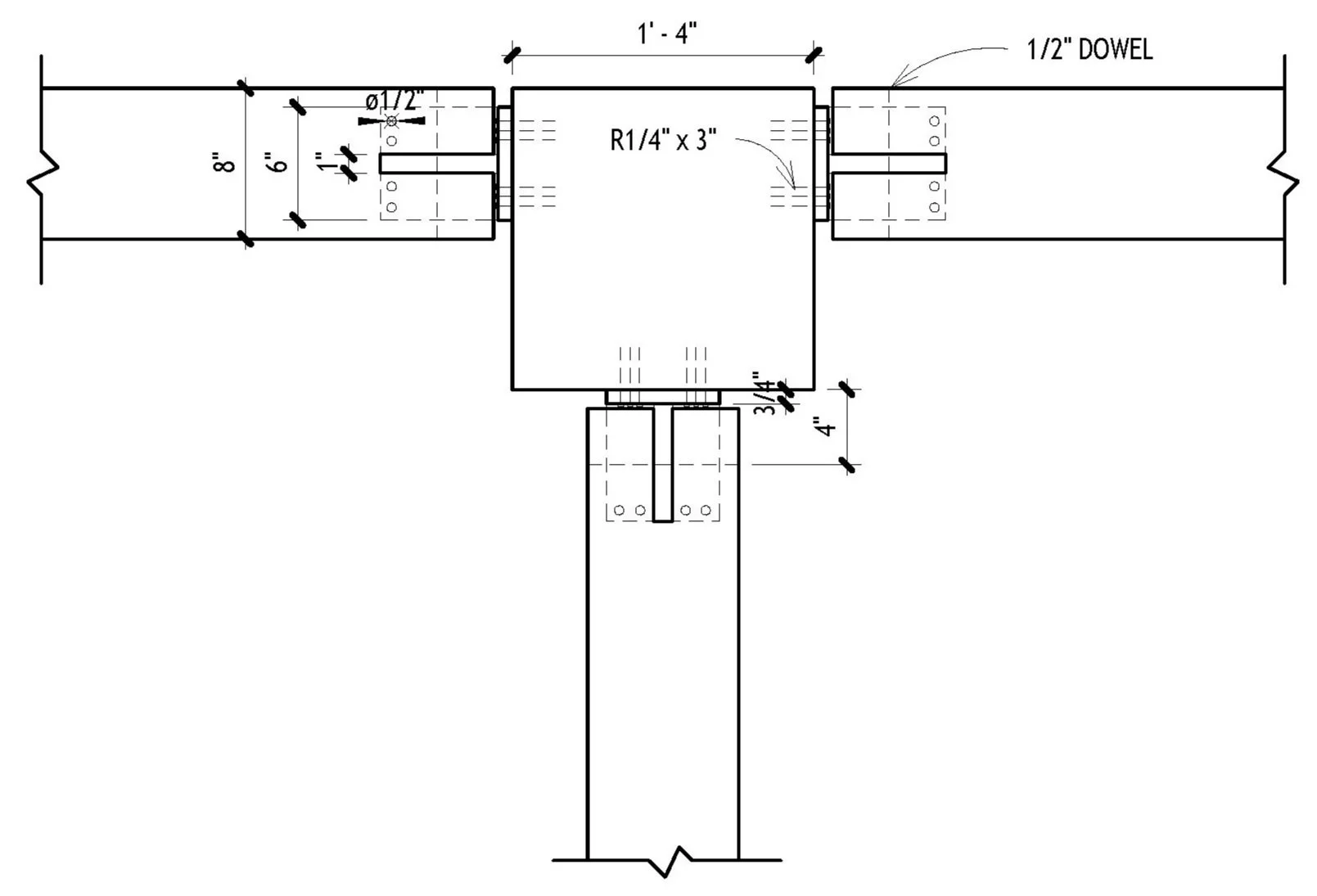

The connection detail that I designed is a 3-direction beam to column heavy seated knife plate connection that resembles the hardware commercially available from Simpson. The purpose of this connection is to transfer vertical load from the wood beam to the wood column. It accomplishes this by utilizing one variation of a fabricated steel connection consisting of bearing plates that support the beam and is face-mounted to the column with screws. The beam bears on the bearing plate and is positively connected to the steel knife plate with dowel-type fasteners and secured using screws. Some other details about this connection are that the capacity of the connection is dependent on the perpendicular-to-grain bearing capacity of the beam at the bearing plate.

This type of connection can be concealed or displayed at the joint. To conceal it, more fabrication of the glulam beams is required prior to installation. However, this does simplify the installation process because there is no need to locate where to install the steel connection for each beam. There are pros and cons to both. For this assignment, I have simplified the detail by allowing the connection to be visible, therefore removing the need for routing out the interior faces of the beams and column.

The reason I selected this specific connection is because of my study of the T3 Minneapolis project during the precedent assignment. This was one of the first mass timber buildings, and it was interesting to learn how they designed these connections early on and compare them to the vast variety of available connections today. The T3 project did not have many details or dimensions to pull from, so it required me to dive deeper into the understanding of how to use a knife plate connection and ultimately custom design one for my own liking, which is the result of this project.

Existing Hardware from Simpson

My Connection Details

T3 Minneapolis Connection Image

1/4 scale Final Model Images

My Connection 3D Model

Detailed Front View

Detailed Top View